Premium Products

As an authorized distributor of compressed air products in New Jersey, we fully support the sales and service of industrial gas and air compressors, compressed air treatment equipment, vacuum pumps, compressor service and parts and piping installation solutions.

Airmatic Compressor is recognized annually as one of the world’s most sustainable companies and its products help customers to achieve sustainable productivity in a wide range of markets, including general engineering, manufacturing, life and sciences, food and beverage, technology, process industries, automotive, electronics, oil and gas, and much more.

Compressor Technologies

No posts to display

No posts to display

No posts to display

No posts to display

Industrial Air Compressors

Industrial air compressors are safer, more powerful, and more convenient than other energy alternatives, which is why over 70% of all manufacturers rely on some form of an air compressor system. They’re also extremely versatile and can operate at high temperatures, which makes them suitable for a variety of industrial settings and environments.

The following guide explains different types of air compressors, their applications and benefits, and which factors you need to consider before purchasing one.

Types of Air Compressors and Technologies

Air compressor technology has advanced significantly since its earliest design, and with each innovation, systems also become more specialized and diverse. Industrial air compressors have a variety of options available when it comes to the design, pressure level, auxiliary features, and functionality, which means they can be adapted to nearly any industrial application.

Today the most common types of industrial air compressors include:

- Oil-Injected Rotary Screw Compressor: This system incorporates mating screws and uses oil to seal, cool and lubricate.

- Oil-Free Rotary Screw: Also incorporating mating screws, oil-free rotary screw air compressors work by separating the compression chamber from the drive and bearing system so that no contaminants are mixed into the compressed clean air.

- Scroll Compressor: Specifically designed to compress air in a circular motion, scroll compressors, also providing oil free air, offer a smooth consistent downstream flow of clean air.

- Rotary Tooth Compressor: These systems contain two tooth shaped rotors that synchronously move in opposite directions to maximize air compression throughout the chamber. This technology is typically oil free.

- Reciprocating Piston Compressor: Available in both oil lubricated and oil free versions, this technology uses pistons and a crankshaft through a reciprocating motion to compress air.

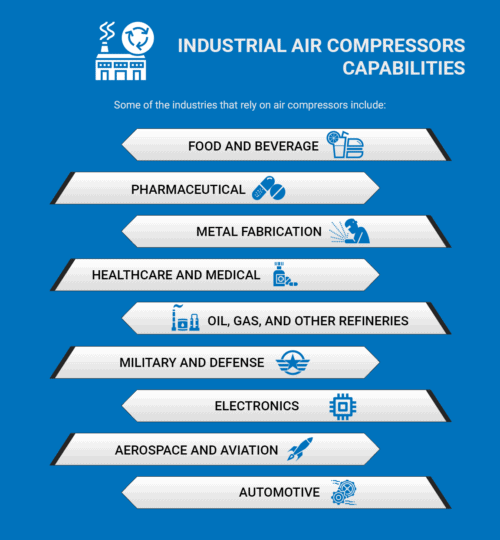

Industrial Air Compressors Capabilities

Because there are a variety of industrial air compressor technologies on the market, businesses can find an option that is uniquely designed to suit their needs. For instance, rotary-tooth and rotary-screw, both deliver oil-free compressed air which are popular in the pharmaceutical, food, beverage, and chemical industries because they produce exceptionally clean air and limit the risk of cross-contamination.

Reciprocating piston compressors fit well into auto repair and autobody applications because they are low cost and provide a long service life. Oil injected rotary screw make up the bulk of the market because they are quiet and handle varying loads efficiently. Likewise, scroll compressors are becoming increasingly popular with HVAC systems because they maintain consistent heating and cooling settings throughout large areas.

Some of the industries that rely on air compressors include:

- Food and Beverage

- Pharmaceutical

- Metal Fabrication

- Healthcare and Medical

- Oil, Gas, and Other Refineries

- Military and Defense

- Electronics

- Aerospace and Aviation

- Automotive

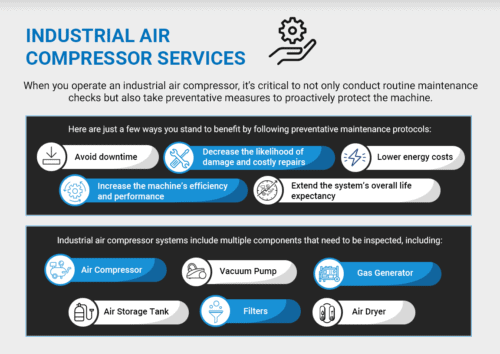

Industrial Air Compressor Services

When you operate an industrial air compressor, it’s critical to not only conduct routine maintenance and checks but also take preventative measures to proactively protect the machine.

Here are just a few ways you stand to benefit by following preventative maintenance protocols:

- Avoid downtime

- Decrease the likelihood of damage and costly repairs

- Lower energy costs

- Increase the machine’s efficiency and performance

- Extend the system’s overall life expectancy

Industrial air compressor systems include multiple components that need to be inspected, including:

- Air compressor

- Air dryer

- Vacuum pump

- Gas generator

- Air storage tank

- Other accessories

All these components need to be thoroughly tested and reviewed according to the manufacturer’s recommended maintenance schedule. If you adhere to the prescribed upkeep, you can ensure your system runs smoothly and protects your business’s bottom line.

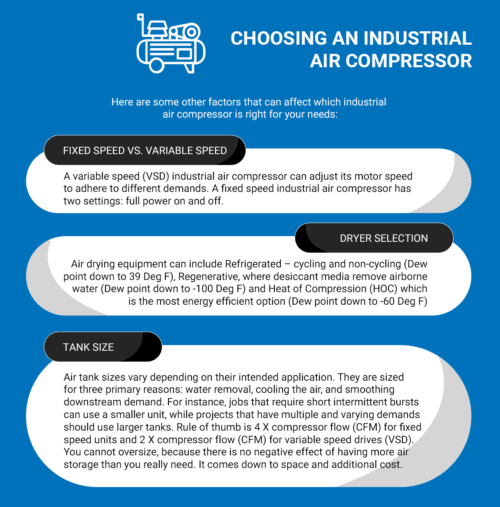

Choosing an Industrial Air Compressor

There are many factors to consider when choosing the right industrial air compressor. Large-scale industrial projects typically require air compressors with higher flow capabilities than commercial air compressors. As an example, you can calculate the flow (CFM) requirements by adding the cubic feet per minute (CFM) demand of all machinery requiring compressed air.Then add a 25% safety factor for error and potential increase in demand.

Also, your pressure setting should be high enough to satisfy tool or equipment peak load requirement. Compressed air audits are invaluable in determining how much air at what pressure is needed for existing systems. Data logging is a fairly simple process that Airmatic offers its customers.

Here are some other factors that can affect which industrial air compressor is right for your needs:

- Fixed Speed vs. Variable Speed

A variable speed (VSD) industrial air compressor can adjust its motor speed to adhere to different demands. A fixed speed industrial air compressor has two settings: full power on and off. - Dryer Selection

Air drying equipment can include Refrigerated – cycling and non-cycling (Dew point down to 39 Deg F), Regenerative, where desiccant media remove airborne water (Dew point down to -100 Deg F) and Heat of Compression (HOC) which is the most energy efficient option (Dew point down to -60 Deg F) - Tank Size

Air tank sizes vary depending on the device’s intended application. They are sized for three primary reasons: water removal, cooling the air, and smoothing downstream demand. For instance, jobs that require short intermittent bursts can use a smaller unit, while projects that have multiple and varying demands should use larger tanks. Rule of thumb is 4 X compressor flow (CFM) for fixed speed units and 2 X compressor flow (CFM) for variable speed drives (VSD). You cannot oversize, because there is no negative effect of having more air storage than you really need. It comes down to space and additional cost.

Industrial Air Compressors at Airmatic Compressors

Airmatic Compressors is a New Jersey-based distributor of compressed air products. Our dedicated staff offers full repair and maintenance services for industrial air and gas compressors, air treatment equipment, and vacuum pumps, in addition to providing compressor and installation service. Our knowledgeable and experienced staff is an invaluable resource for information about buying new compressed air equipment for your business.

We take pride in our company’s dedication to environmental sustainability!

To learn more about industrial air compressors, including eco-friendly options, contact us today.

Our Mr. Nestor plan is named after our Founder, Mr. Nestor Vowteras, who built our company delivering the highest level of customer service. The annual renewal of the 10-year preventive maintenance agreement will provide a 10-year airend parts and labor warranty and a Bumper-to-Bumper Warranty for the first 5 years of coverage. 10 years of keeping your maintenance budget fixed and your airend fully covered with a 5 year Bumper-to-Bumper Warranty is why this is the industry’s most customer focused service and warranty plan. This is a service plan that would make our Founder proud.

Our Warranties